A factory tour with ABMT Textiles

We recently caught up with ABMT Textiles, a major player in the textiles industry with global headquarters and a manufacturing plant on Ferris Road, Melton, and operations in New Zealand, Asia, the US and the UK.

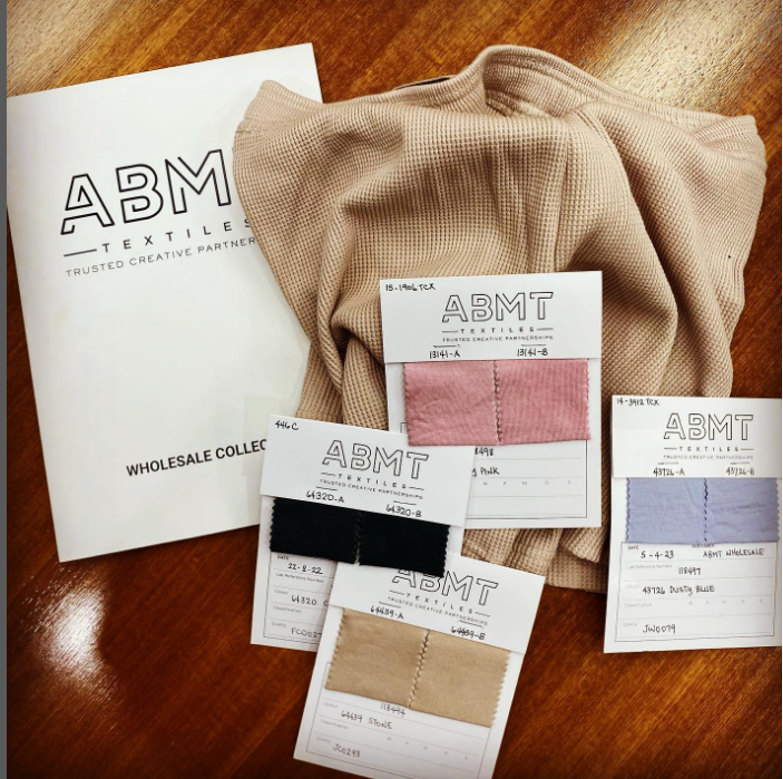

ABMT Australia is home to MerinoEdge and is a recognized global leader in natural fibre circular knit manufacturing. The company is certified under the Oeko Tex standard and services a diverse customer base covering local fashion retailers through to global sports and outdoor brands.

Located 40kms west of Melbourne’s CBD, the Australian base is ABMT’s hub for research and development, as well as being the manufacturing base for ABMT’s Merino Wool, Organic Cotton and Fashion Fabric programs.

During our factory tour with Julian Collins, Sales & Business Development Manager at ABMT, Julian explained, “We’ve been in operation in Melton for nearly 20 years. There’s always been a strong interest within the local community in what we do at ABMT and many of our team members live locally and have been with us for a long time.

“Some have been trained here at ABMT whilst others came to us with vast experience and specialist skills having worked in large textiles and knitting factories overseas.”

ABMT’s extensive assortment of knitting machines, in single jersey, double knit and jacquard, combines with the latest in low-liquor-ratio dyeing machines and broad finishing capabilities such as compaction, decatising and brushing, provide an almost limitless scope in circular knits.

ABMT currently employs close to 60 full-time staff on site at Melton and is projecting that this number could increase significantly as they plan for an expansion of their operations on Ferris Rd.

A key advantage of the company’s local Australian production is that they have the flexibility to offer minimum order quantities as low as 500 metres. This enables ABMT to support emerging Australian designers and provide fast turnaround solutions for existing brands.

Julian says that at the other end of the customer demand spectrum, ABMT’s production capacity is geared towards its partnership with major retail brands.

“Our bulk dyeing can handle up to 3000mts of fabric per batch.

“In peak periods we can produce up to 100,000mts (100km) per week.”

With a full on-site five-stage water treatment plant, up to 85% of ABMT water can be reused, either back through the manufacturing process or via western water’s grey recycled water programs for agriculture, parklands and industry.

ABMT Australia’s website states its belief that the environment does not have to be sacrificed for quality, and the company’s ambition is to create quality products with minimal environmental impact, by promoting responsible farming, cleaner manufacturing and utilizing the benefits of sustainable natural fibres.

To ensure consistently high quality, both the start and the end of the production process involve strict testing and quality control processes, as samples are analysed and every meter of product passes by the eye of ABMT’s inspection team.

During our tour Julian Collins explains what ABMT’s sustainability focus means in practice.

“We are always looking for the next improvement and we are focused not just on our own site but also on our supply chains,” he said.

“This means that we identify sustainable, local growers and only use organically grown or Australian Good Earth Cotton and Aussie Merino Wool. Being an Australian Certified Organics operation is fundamental to our brand.

“We are currently planning further improvements with our fibre growing partners that could take our supply chain emissions into the positive or “credit” range rather than just being at a low emission level or carbon neutral.”

The time between 2021 and 2022 was a particularly busy period for the organisation as ABMT improved their factory skylights, installed a 1,400 panel, 464KW solar system and launched ABMT Apparel, an authentic, responsible, transparent and ethical vertical apparel solution with sewing factories in Sunshine and Thomatown.

“The solar panels provide up to 30% of our electricity and whilst they bring operational cost savings this was not the main reason behind the upgrade, being sustainable and responsible is part of our DNA at ABMT,” Julian explained.

It was an absolute pleasure to be able to visit ABMT. Beyond the words and images in our ABMT business spotlight, we thought there is no better way of summarising the company’s know-how and impact then by sharing the this story and video from one of ABMT’s key partners:

Country Road on Instagram: "The Melbourne-made reissue of our 90s Heritage Sweat.

During the Covid Pandemic, when many brands were restricted by interrupted supply chains and had no access to stock from overseas markets, Country Road decided to relaunch its heritage sweater with the support of ABMT’s local manufacturing capability. Watch the film to see how it came back to life.